Plastic and the Environment

A Sustainable Approach to Plastic Waste

When you Google the term “Plastic and the Environment” you are met with a deluge of negative headlines that make it seem like any sort of sustainable approach to plastic waste management is a lost cause. The environmental toll of our increasing dependence on plastics is, indeed, frightening. For some, the solution is to choose plastics or to choose the planet – feeling that the two are mutually exclusive. However, this is not a truly sustainable approach to finding a solution that works for today.

It isn’t feasible for us to stop using plastic completely. This is especially true when you consider the environmental impact of transporting plastic alternatives such as glass jars. Did you know that to transport equal amounts of product, it would take 26 truckloads for glass packaging as opposed to just one truckload for the same volume of flexible packaging?

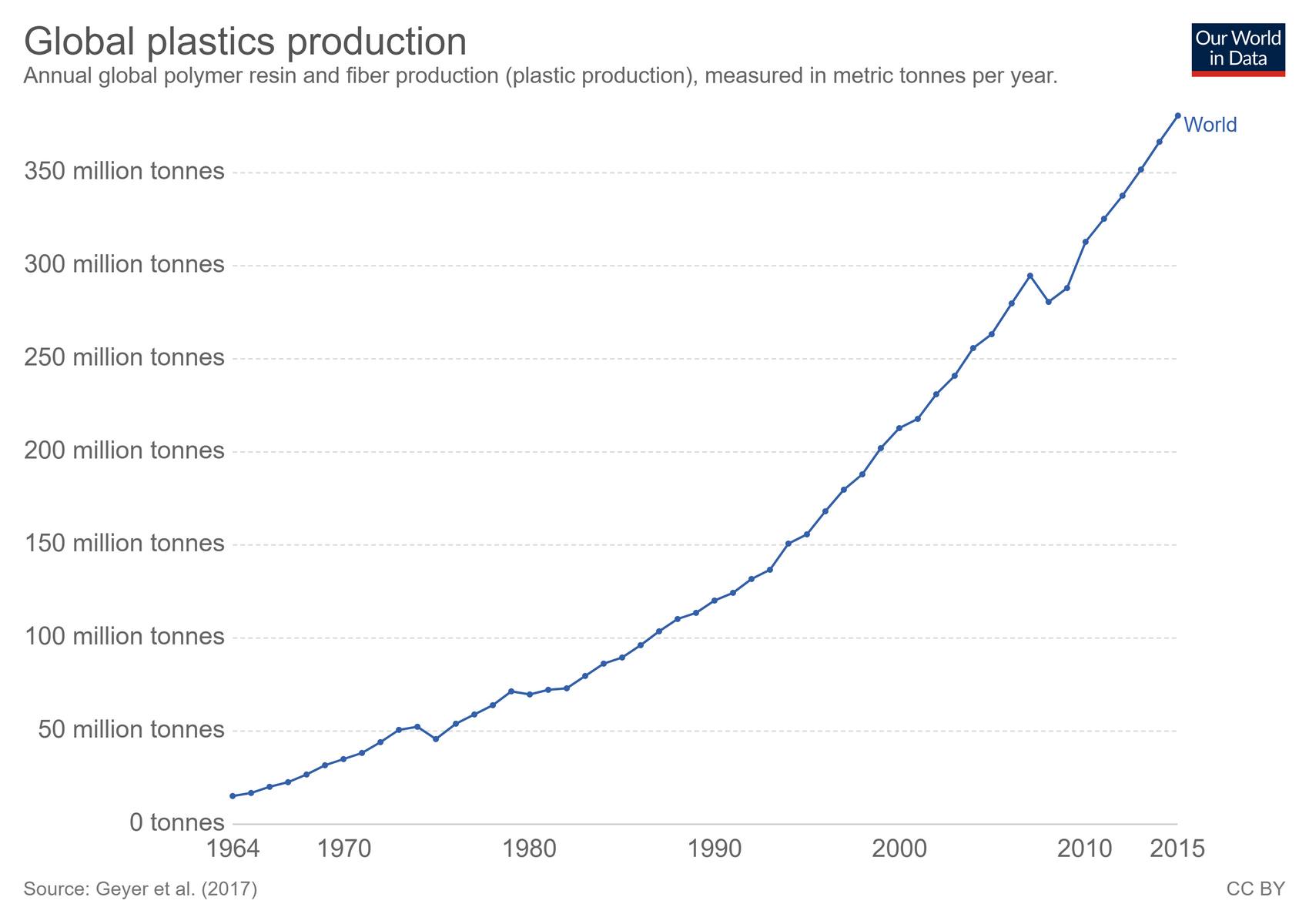

With 7.2 billion people on the planet, we use a huge amount of plastic – and that isn’t likely to change, so we need to rethink how we are making our plastics. Worldwide, the annual production of plastic in 2012 was more than 6 billion lbs. This is enough plastic to circle the earth one foot wide and one foot deep over 450 times! By 2016, plastic consumption was estimated to be well over 738 billion pounds.

BioFlex™ is a solution for today, that recovers our post-consumer plastic waste.

I want to Learn More About Plastic

What Makes BioFlex™ Flexible Packaging Any Different?

Plastic is a big part of our daily lives. From safely transporting important medical supplies and medications to preserving our food and cutting down on wasted food, plastic has become a necessary component of our world. That’s why we believe in finding a solution that allows us to utilize the many benefits offered by plastic without harming our planet further.

BioFlex™ is that solution.

BioFlex™ is flexible packaging that is designed to be disposed of into a landfill at its end of life. Due to its construction and the energy and cost required, conventional flexible packaging is unable to be recycled. Additionally, conversion to biogas is more valuable than recycling in some applications.

BioFlex™ contains the same benefits of a low environmental cost as a conventional flexible package. However, what makes it unique is its ability to provide end of life value through its composition of special additives that allow it to increase biogas production under the conditions of a modern landfill with a landfill gas capture system. In addition to clearing greater amounts of landfill space, this process produces landfill gases, which can be captured by capped collection technologies within the modern landfill environment.

BioFlex™ is an easy to use product that requires no change in consumer habits. Moreover, manufacturers and processors do not require any special equipment or need to make any adjustments to the packaging process. Like standard conventional flexible packaging, all consumers must do is dispose of it properly in conventional garbage collection, and the landfill gas collection technologies will take care of the rest!

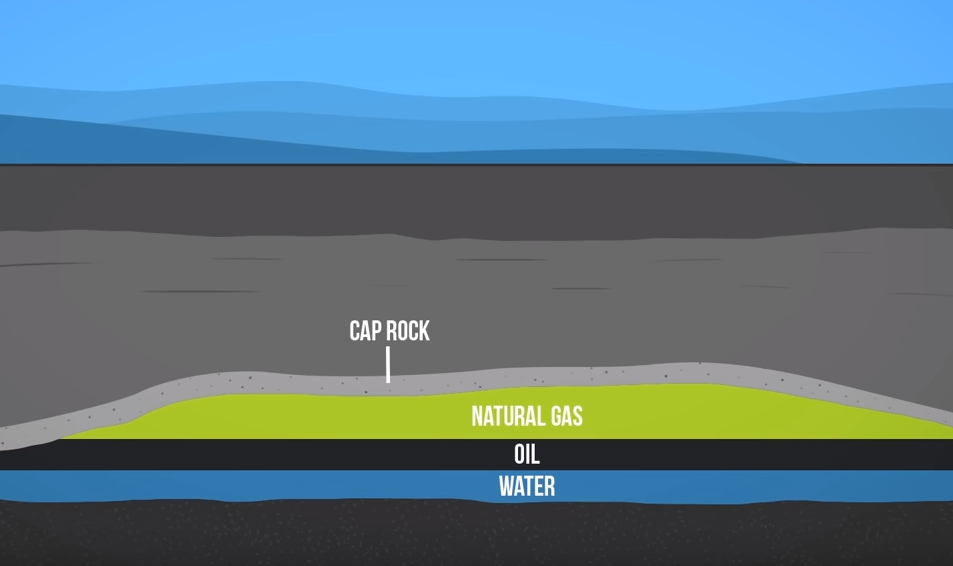

BioFlex™ Increases Biogas in a Landfill

BioFlex is a special variety of flexible packaging that attracts landfill-specific microbes that consume the plastic. From consuming the BioFlex™ material, these microbes excrete methane that can be captured for future energy use.

A conventional plastic undergoes some extent of biogas release through these microbes and other environmental factors like light, heat, moisture, and oxygen. However, the unique composition of BioFlex™ produces biogas 22 times faster* than conventional packaging.

The Better Way to Do Plastic Packaging – BioFlex™ Creates Energy!

BioFlex™ is engineered to accelerate the natural microbial process creating biogas in modern capped landfills. This means that BioFlex™ will contribute to more biogases in the landfill that can be converted into natural gas.

Most landfills are equipped to capture the Land Fill Gas (LFG) produced by the BioFlex™ package and converted into renewable and sustainable energy. In the U.S. there are currently 619 modern landfill projects, and in Canada, there are 64 projects.

Today, over 80% of plastics, once disposed of, end up at the landfill. Landfills are capturing the biogas from decomposing garbage that would otherwise be released into the atmosphere. BioFlex™ is the perfect solution for utilizing today’s readily available energy conversion infrastructures in almost all the metropolitan cities in North America.

The convenient and effortless disposal method makes BioFlex™ the most responsible and sustainable choice for packaging any products in plastic.

BioFlex™ is a practical sustainable solution for today. BioFlex™ packaging can be recycled in some cases when it is made from a single structure. When it’s not possible to recycle BioFlex, it ends up in the landfill, which helps to create energy that can be used to power entire neighbourhoods and electric cars!

BioFlex™ is a Solution for Today

The journey to BioFlex™ has taken over a decade and it still isn’t over! We are continuously innovating so that we can provide sustainable solutions for you and our planet. We like to think our journey has been a labour of love and a commitment to protecting our planet for current and future generations.

Whether you are a consumer who wants to be more educated on living a sustainable life or a manufacturer looking to improve their own practices, BioFlex™ Flexible Packaging is a truly sustainable solution.

*BioFlex™ has been shown to produce biogases 22 times faster than conventional plastic in the ideal conditions of an anerobic digestor landfill over the course of 2.13 years, using the ASTM D5511-12 test. When disposed of in a landfill with modern biogas capture technologies, this energy can be harnessed as a source of renewable energy. Such a facility may not exist in your area.