About BioFlex™

A sustainable approach

Our Mission

It is our mission to make Today’s Packaging Waste Tomorrow’s Energy*.

To accomplish this pragmatically, we designed a solution that works with today’s modern landfill infrastructure.

Whether you are a consumer or a brand-owner, you can join our movement by turning today’s packaging waste into tomorrow’s clean energy.

Intended for Discard

BioFlex™ Reduces Environmental Impact by Throwing it Away!

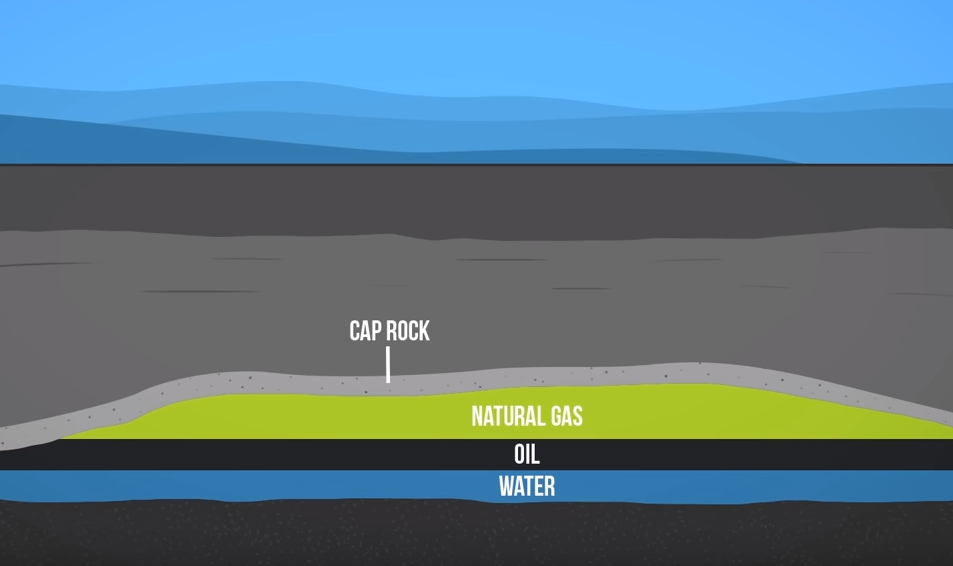

BioFlex™ flexible packaging has a responsible clean-energy end-of-life solution. This product was designed to take advantage of modern waste management infrastructure. The energy from your package can be harnessed and converted into clean energy within today’s modern landfill environments*.

Follow along our journey to develop a sustainable solution that provides all the benefits of conventional plastic packaging while creating a sustainable clean-energy end-of-life solution.

1.3 M

Landfill gas (LFG) energy projects produced enough energy to power 1.3 million homes in the US in 2015

24/7

Modern landfills can constantly generate biogas and not rely on environmental factors such as sun or wind

619

There are 619 energy projects in 2019 a 67% increase from 370 in 2017

60 to 90%

LFG energy projects can capture 60 to 90% of the methane from decomposing garbage that would otherwise be emitted to the atmosphere