In most cases, flexible packaging achieves the necessary protective properties with the lowest environmental footprint of all comparable packaging options because significantly less raw material is required to produce it.

For example, the materials required to package 60 lbs of beverage are:

BioFlex™ packaging has been shown to increase the rate of Biogas production in standardized test methods that simulate ideal landfill conditions*!

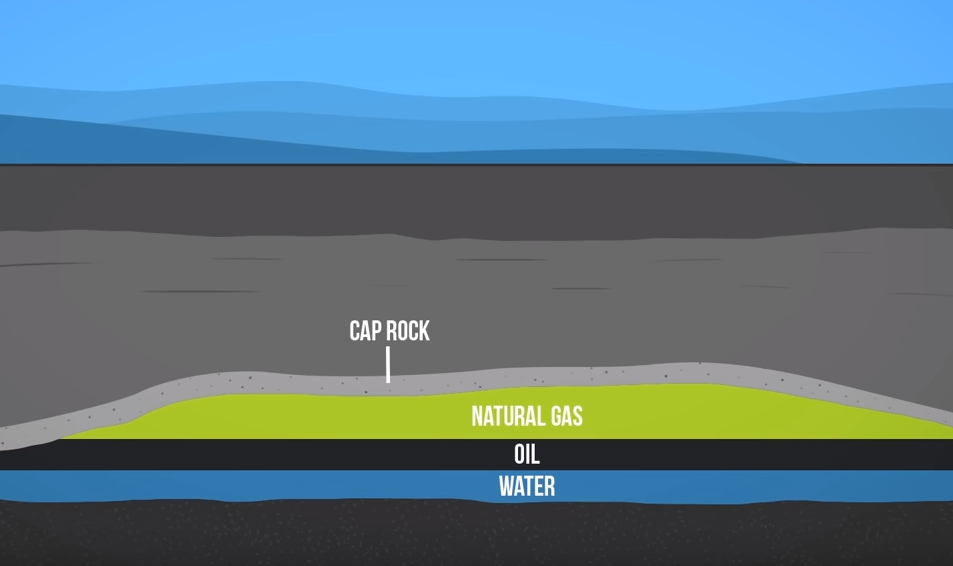

Raw natural gas contains many components such as ethane, propane, butane, and pentane. Ethane is abundant in many natural gas wells and is widely used as the feedstock for polyethylene production in North America.

Plastics are composed of elements such as carbon, oxygen, and nitrogen. Each plastic molecule is composed of thousands of atoms bonded together in repeating units. Naturally occurring materials such as wood, silk, and DNA are also composed this way.

Most flexible packaging contains multiple layers of film composed of different types of plastic. This design allows very high-performance packaging to be produced out of minimal materials. High-performance packaging protects food from moisture and oxygen, preventing it from spoiling.

Plastic Recycling Chart |

||||||

|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

| Polyethylene Terephthalate | High-Density Polyethylene | Polyvinyl Chloride | Low-Density Polyethylene | Polypropylene | Polystyrene | Other, Nylon BPA, and Polycarbonate |

| Uses: Soft drinks, water bottles, cooking oil, salad dressings, microwavable food trays | Uses: milk jugs, yogurt, cleaning agents, laundry detergents, shampoo bottles | Uses: cooking oil, clear food packaging, mouthwash bottles | Uses: shopping bags, bread bags, carpet, clothing, furniture | Uses: Ketchup bottles, medicine and syrup bottles, drinking straws | Uses: Disposable cups and plates, egg cartons, take out containers | Uses: Acrylic, clothing, fiberglass, food containers |